Replacing a pressure plate on a Case SR220, SR250, SV250, SV300, TR320, or TV380 involves several steps. click here for more details on the download manual…..

- A $6,000 Skidsteer Repair?? UGH! Hydraulic lines leaking on Case SV280 Skidsteer Loader. A $6000 repair? Southern Maryland, USA.

- Case SR250 attachment removal & mounting procedure It is recommended to refer to your machine’s Owners Manual. This tutorial is to be followed at you own risk. Nor YouTube or this …

Here’s a reverse order guide to help you understand the process:

### 6. Final Assembly

– Reattach any covers or shields removed during the process.

– Ensure all bolts and fasteners are tightened to the manufacturer’s specifications.

– Reconnect the battery and ensure all electrical connections are secure.

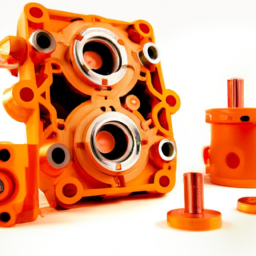

### 5. Install New Pressure Plate

– Align the new pressure plate over the flywheel, ensuring it fits properly.

– Secure the pressure plate with the appropriate bolts, tightening them in a crisscross pattern to ensure even pressure.

### 4. Remove Old Pressure Plate

– Unscrew the bolts securing the old pressure plate to the flywheel.

– Carefully lift the old pressure plate off the flywheel, taking care not to damage any surrounding components.

### 3. Access the Pressure Plate

– If necessary, remove any components that obstruct access to the pressure plate. This may include the transmission or certain engine covers.

– Drain the hydraulic fluid if required, depending on your machine’s design.

### 2. Prepare the Work Area

– Ensure the machine is on a stable and level surface.

– Gather necessary tools (socket set, torque wrench, etc.) and replacement parts (new pressure plate, gaskets, etc.).

### 1. Safety Precautions

– Turn off the engine and remove the key.

– Engage the parking brake and secure the machine to prevent any movement.

– Wear appropriate personal protective equipment (PPE) such as gloves and safety glasses.

### Additional Notes:

– Always consult the specific service manual for your machine model for detailed instructions and torque specifications.

– If you’re not confident in performing this repair, consider seeking assistance from a qualified technician.

By following these steps in reverse order, you can effectively replace the pressure plate on your Case equipment.

The Mass Air Flow (MAF) sensor is a critical component in modern internal combustion engines that plays a vital role in optimizing engine performance and efficiency. Its primary function is to measure the amount of air entering the engine, which is essential for the Engine Control Unit (ECU) to determine the appropriate fuel-to-air ratio for combustion. This ratio is crucial for achieving efficient combustion, reduced emissions, and overall engine performance.

and efficiency. Its primary function is to measure the amount of air entering the engine, which is essential for the Engine Control Unit (ECU) to determine the appropriate fuel-to-air ratio for combustion. This ratio is crucial for achieving efficient combustion, reduced emissions, and overall engine performance.

Typically located between the air filter and the throttle body, the MAF sensor utilizes either a hot wire or a vane-type design to measure airflow. In a hot wire MAF sensor, a thin wire is heated By an electrical current. As air flows over the wire, it cools down, and the sensor detects the change in temperature. The ECU then calculates the mass of the incoming air based on the amount of current required to keep the wire at a specific temperature. Vane-type sensors operate By using a mechanical vane that moves in response to airflow, providing a direct measurement of air volume.

A malfunctioning MAF sensor can lead to various issues, including poor fuel economy, rough idling, decreased engine power, and increased emissions. Symptoms of a failing MAF sensor may include the Check Engine light illuminating, engine stalling, or hesitation during acceleration. Regular maintenance and timely replacement of the MAF sensor, if needed, can ensure optimal engine performance and longevity.