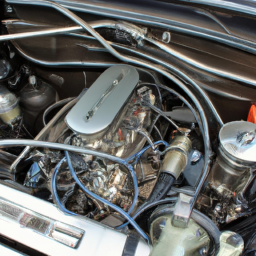

Replacing the anti-roll bar (also known as a sway bar) on a vehicle equipped with a Ford 2701C engine can seem daunting, but with some patience and the right tools, you can do it yourself. click here for more details on the download manual…..

- Variable resistor

- Dodge RAM v Ford F-150 v Chevy Silverado: TUG-OF-WAR Need help buying your next car? Click the following link and my team and I will help you choose your ideal car at a fair price – from …

Here’s a simple, step-by-step guide to help you through the process.

### Tools and Materials Needed:

– **Tools:**

– Socket set (including a ratchet and extensions)

– Wrenches (metric and standard)

– Jack and jack stands

– Torque wrench

– Screwdriver (flathead and Phillips)

– Pliers

– Hammer (optional)

– **Materials:**

– New anti-roll bar (sway bar)

– New bushings (if required)

– Grease (for bushings)

– Penetrating oil (optional, for rusted bolts)

### Steps to Replace the Anti-Roll Bar:

1. **Preparation:**

– Park the vehicle on a flat, level surface.

– Turn off the engine and set the parking brake.

– If you have wheel covers, remove them.

2. **Lift the Vehicle:**

– Use a jack to lift the front of the vehicle. Make sure it’s high enough to work safely under it.

– Secure the vehicle with jack stands to prevent it from falling.

3. **Remove the Front Wheels:**

– Use a socket wrench to remove the lug nuts and take off the front wheels. This will give you better access to the anti-roll bar.

4. **Locate the Anti-Roll Bar:**

– The anti-roll bar is typically a thick metal rod that runs across the width of the vehicle, connecting the left and right suspension components.

5. **Remove the End Links:**

– At each end of the anti-roll bar, you will find end links that connect it to the suspension. Use the appropriate socket or wrench to remove the nuts and bolts holding the end links in place. Keep track of any washers or bushings for reassembly.

6. **Remove the Bushings:**

– The anti-roll bar is usually held in place By bushings mounted on the frame. Use your wrench or socket to remove the bolts securing these bushings. If they are stuck, a little penetrating oil can help.

7. **Take Out the Anti-Roll Bar:**

– Once all the nuts, bolts, and end links are removed, gently wiggle the anti-roll bar free from its mounts. It may require some force, but be careful not to damage the surrounding components.

8. **Install the New Anti-Roll Bar:**

– Position the new anti-roll bar in place. Make sure it lines up with the bushings and mounts.

– Reattach the bushings and make sure they are properly seated. Use grease on the new bushings If required.

9. **Reattach the End Links:**

– Connect the end links to the suspension. Make sure they are installed correctly and tighten the nuts securely.

10. **Reinstall the Wheels:**

– Once everything is securely in place, put the front wheels back on. Hand-tighten the lug nuts.

11. **Lower the Vehicle:**

– Carefully remove the jack stands and lower the vehicle back to the ground.

12. **Tighten the Lug Nuts:**

– Once the vehicle is on the ground, use a torque wrench to tighten the lug nuts to the manufacturer’s specifications (typically indicated in the owner’s manual).

13. **Final Checks:**

– Double-check all bolts and nuts to ensure everything is tight and secure.

and nuts to ensure everything is tight and secure.

– Take the car for a short test drive to ensure that everything feels right and there are no unusual noises.

### Important Tips:

– Always refer to the vehicle’s service manual for specific torque specifications and any additional instructions.

– If you encounter any rusted or stuck bolts, take your time and use penetrating oil to help loosen them.

– If you’re unsure about any step, it’s always a good idea to consult a professional mechanic.

By following these steps, you should be able to successfully replace the anti-roll bar on your vehicle. Good luck, and take your time to ensure a safe and successful installation!

A catalytic converter is a crucial component of a vehicle’s exhaust system, designed to reduce harmful emissions produced By internal combustion engines. Positioned between the engine and the muffler, this device plays a vital role in environmental protection By converting harmful pollutants into less harmful substances before they are released into the atmosphere.

The catalytic converter contains a catalyst, typically made from precious metals such as platinum, palladium, and rhodium. These metals facilitate chemical reactions that break down toxic gases, including carbon monoxide (a poisonous gas), nitrogen oxides (which contribute to smog), and unburned hydrocarbons (which can lead to ozone formation). The converter operates through two primary processes: oxidation and reduction. In the oxidation process, carbon monoxide and unburned hydrocarbons are transformed into carbon dioxide and water vapor. Meanwhile, the reduction process targets nitrogen oxides, converting them into nitrogen and oxygen.

In modern vehicles, catalytic converters are essential for compliance with stringent emissions regulations set By governmental bodies. They not only help in reducing air pollution but also improve the overall efficiency of the engine By optimizing the combustion process. Additionally, a malfunctioning catalytic converter can lead to decreased engine performance, increased fuel consumption, and failed emissions tests, making it a key component for both environmental sustainability and vehicle health. Regular maintenance and checks are crucial to ensure the catalytic converter functions effectively throughout the vehicle’s lifespan.